Every so often a sudden and significant advance happens in the world of tools, and a few years ago was one of those times. It’s called brushless motor technology, and it promises to instantly boost the performance of cordless tools across the board. All tool manufacturers are bringing brushless tools to market right now, and though many cordless tools on store shelves aren’t brushless yet, the new technology is worth looking for. To understand why, you need to understand what brushless is all about in the context of electric motors. You can see the two kinds of motors below, opened a little for visibility during my tool testing.

The Makita drill on the left has traditional brushes, and the Milwaukee on the right is brushless. All the mechanical complexity of brushed design is sidestepped by the mechanical simplicity of internal circuitry.

Traditionally, power tool motors include small, spring-loaded blocks of carbon hidden inside. These blocks are called brushes (even though they look nothing like a “brush” and have no bristles) and they press against the revolving part of the motor, delivering electricity to it as it turns, while helping to create a revolving electrical field. It’s this revolving field inside the motor that makes it spin, and brushes have been an integral part of making this happen for more than a century. But as useful as they’ve been, brushes pose two major limitations. They wear out and they cause friction.

Since brushes are designed to rub against revolving internal motor parts, they wear out in time. That’s just the way it is, and if brushes aren’t replaced in time, any tool motor will be ruined with continued use. Another problem with brushes is the energy they waste. Rubbing means friction and sparking, and this translates to less work done on each battery charge, all else being equal.

Brushless tools sidestep both the problem of wear and the problem of friction, and they do this with a much simpler design than older, brush-style motors. The two kinds of drills show side by side above show the difference, even if you don’t know anything about motors you can certainly see the difference.

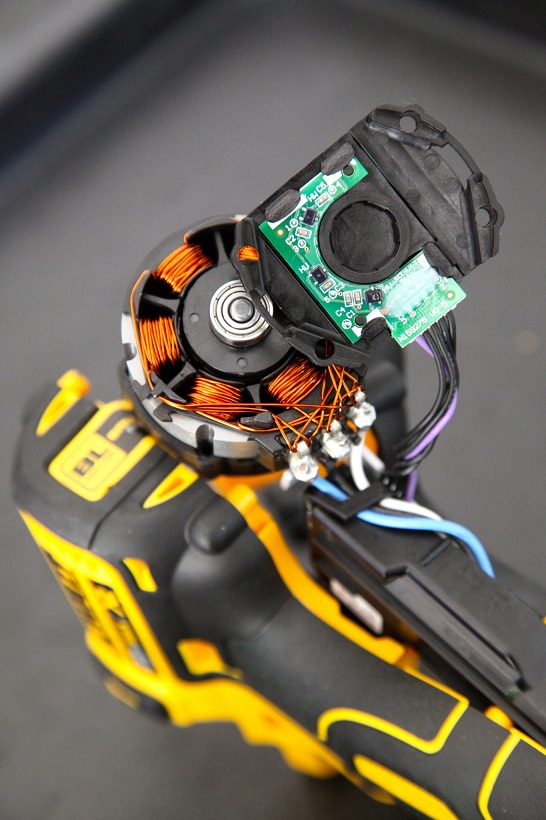

What could be simpler than this? The internal part of a cordless drill with a brushless motor shows just how simple this approach is. Longer working life and less internal friction are the reasons brushless power tool motors are here to stay.

Instead of the mechanical system of brushes, springs and other parts that make DC electric motors spin, brushless tools use electronic circuitry to accomplish the same thing with far fewer moving parts. The results are some pretty tall claims from manufacturers for longer tool life and more work accomplished per charge. Brushless tool motors are supposed to last at least 1000% longer than brush-style motors before wearing out, and they’re supposed to deliver 50% more work from a given battery pack before charging is necessary. But claims are easy to make, and that’s why I decided to check out the reality myself.

Opening up this DEWALT brushless drill shows the simpler motor of brushless power tools. The circuitry with the wires leading from it take the place of mechanical brushes and springs.

To test brushless tool speed and endurance, I fitted an 18 volt Milwaukee FUEL 2604 brushless drill with the same kind of 9/16” drill bit I put into two new, comparable brush-style drills: the 20 volt DeWALT DCD989 and the 18 volt Makita BHP454. All three tools had fully charged 3.0 amp-hour batteries at the beginning of each test run. I measured how many 10-inch deep holes I could drill in the end of hard maple logs on a single charge, and how long it took to drill these holes. I repeated this test several times, averaging the production and speed numbers for accuracy. Bottom line: The Milwaukee brushless FUEL drilled ran 40% longer than the best competing brushed drills on the same size battery, and 22% faster than the next best model. For a more detailed look at the internal technical differences between brush versus brushless, and to see exactly how all three drills compared with each other.

The performance gains delivered by brushless tools come by reducing the amount of energy lost in the form of heat, and converting this energy instead into work. Besides the measurable differences in speed and endurance, you can also feel the difference in your hand while using the drills under load. While lots of heat was blasting out of the vents on the brush-style drills while drilling, the Milwaukee ran noticeably cooler – just as you’d expect.

Post time: Jun-16-2022